Rocket Lab

Opening access to space to improve life on Earth

DCVC backed Rocket Lab in their $140M Series E in Fall of 2018 as they scaled up their rocket manufacturing and prepared for back-to-back launches in November and early December. These launches went flawlessly, launching a total of 20 satellites, including key NASA payload. We invested in Rocket Lab because they provide critical enabling infrastructure for the armada of small satellites trying to make it to orbit. The company has accomplished this with breakthroughs in rocket materials and machine-learning-assisted manufacturing – including carbon fiber rocket bodies and fully 3d-printed rocket engines – as well as higher quality, more cost effective, “full stack” software and process for launch operations. DCVC partners are only half-joking when they refer to Rocket Lab as a “software leader disguised as a rocket leader.”

Rocket Lab will change the world through their cargo: small satellites for environmental monitoring, communications services, weather tracking, natural disaster detection, and much more – including their key partnerships with existing DCVC companies Capella Space and Planet Labs.

Moore’s Law and Mobile Devices Gave Birth to a Smallsat Revolution

Electronic components’ falling size and cost, driven by Moore’s Law and massive cost reductions in mobile device manufacturing, have driven the development of small satellites (“smallsats”) — satellites weighing less than 500 kg — since the mid-2000s. While universities launched most smallsats through 2013, major commercial growth (a ninefold jump from 2013 to 2014 alone) has accounted for most launches since then. DCVC companies like Planet and Capella Space are building satellite swarms that generate actionable earth observation data for a wide variety of applications, and more companies are entering the space every year.

While the demand for small satellite launches has been skyrocketing, the frequency of orbital launches has fallen 43% from its 1967 peak. Last year, the United States launched only [29](https://space.skyrocket.de/doc_chr/lau2017.htm) rockets. This mismatch means that existing launch services only address about [52%](http://interactive.satellitetoday.com/via/july-2018/smallsat-launch-market-to-soar-past-62-billion-by-2030/) of current demand for small satellite launches.

Smallsat launch demand will further increase in the coming years. Of the 30+ commercial smallsat operators, [only 2](http://interactive.satellitetoday.com/via/july-2018/smallsat-launch-market-to-soar-past-62-billion-by-2030/) have partially or completely launched their constellations. The remaining 28 still need to get their satellites in space. Smallsats have an operational lifespan of 2 to 5 years, so after initial installation, smallsat operators will need recurring, continuous launches to keep their constellations operational. Researchers say that “the low availability of launch opportunities for small satellites is often regarded as [the most significant threat](https://www.researchgate.net/publication/264537134_Small_Satellite_Launch_to_LEO_A_Review_of_Current_and_Future_Launch_Systems) to the continued growth of this sector”.

Smallsats have traditionally reached [space](https://www.researchgate.net/publication/264537134_Small_Satellite_Launch_to_LEO_A_Review_of_Current_and_Future_Launch_Systems) by ridesharing with multiple other smallsats to an agreed-upon orbit, or piggybacking as a secondary payload on a primary payload’s launch. In ridesharing, problems with any of the payloads can delay the launch date, and the orbit will probably be suboptimal for all of the smallsats. In piggybacking, the primary payload sets the orbit, so smallsats must wait — sometimes years — for a suitable launch. Secondary payloads also take a backseat to the primary payload: they won’t be delivered if it inconveniences the primary payload, and the company might have to pay prohibitively high insurance rates against damaging the primary payload. In short, smallsat launches are inconvenient, infrequent, and subject to delays and deprioritization.

The Rocket Lab Advantages: Smart Software, Manufacturing Cadence and Cost Reduction, and Reliable and Frequent Launch… Driving a Breakthrough in Launch Cost

“The key element that’s always been missing in spaceflight is frequency, and with frequency comes cost reduction.” — Rocket Lab CEO Peter Beck

Rocket Lab is making frequent, inexpensive smallsat launches possible by having designed their new small launch vehicle — the Electron rocket — from the ground up. Rocket Lab has cut launch costs by more than 95%, with a launch price in single digit millions of US dollars instead of the standard [$130 million](https://www.rocketlabusa.com/about-us/) to guarantee a ride to space. The company has accomplished this by optimizing four critical elements of their rocket: its components, materials, manufacturing, and launch process, with advanced software threaded through and behind all of these aspects.

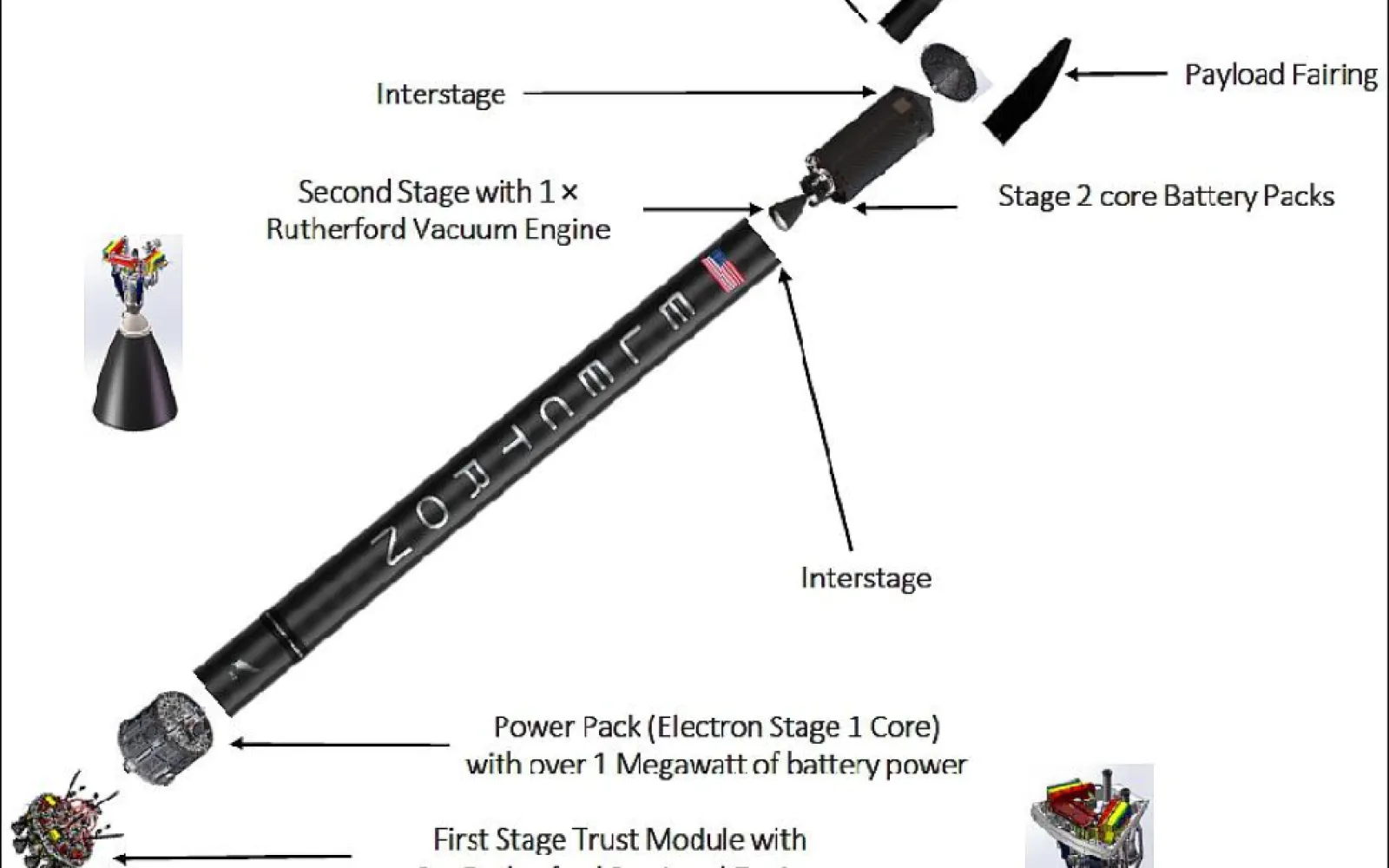

Rocket Lab’s breakthroughs start with their lightweight components and materials. The company designs and makes their own miniaturized power and electronics systems, including their own guidance, navigation, and control systems. They build their [computer systems](https://directory.eoportal.org/web/eoportal/satellite-missions/content/-/article/electron-launcher-of-rocket-lab) with field programmable gate arrays — integrated circuits whose hardware function engineers can change with software. FPGAs enable mass customization while retaining standard hardware, which keeps costs low. Rocket Lab’s Rutherford engine also uses an electric turbopump to pressurize fuel in its combustion chamber. This [improves engine efficiency](https://www.popsci.com/rocket-labs-got-3d-printed-battery-powered-rocket-engine) from the standard 60% to 95%. This [hybrid design](https://www.spaceflightinsider.com/missions/commercial/rocket-lab-electron-rutherford-peter-beck-started-first-place/) makes the engine more thermodynamically simple, and the electric turbopump can be modified and optimized with software in ways mechanical gas pumps cannot be.

All of the Electron’s primary structures are made of carbon fiber — including the payload fairing — and this reduced weight translates to a reduced launch cost. One major pivot from traditional rocket design is Rocket Lab’s carbon composites fuel tanks, which engineers have traditionally avoided — damage to carbon fiber tanks can cause the liquid oxygen they contain to explode. Rocket Lab has developed a lightweight [carbon fiber-reinforced polymer] that holds the liquid oxygen securely. “The [thickness] of the wall of the tank is just slightly larger than the thickness of your credit card,” says CEO Peter Beck. A carbon composite tank also holds the RP‑1, the refined kerosene that reacts with the oxygen to propel the Rutherford engine.

Nearly every part of the Rutherford engine is made with electron beam melting, a 3D printing process capable of making lightweight components with geometries unreachable by traditional manufacturing processes. Rutherford is the [first](https://directory.eoportal.org/web/eoportal/satellite-missions/content/-/article/electron-launcher-of-rocket-lab) oxygen/hydrocarbon engine to use 3D printing for all primary components of its combustor and propellant supply system — [including](https://directory.eoportal.org/web/eoportal/satellite-missions/content/-/article/electron-launcher-of-rocket-lab) the regeneratively cooled thrust chamber, injector pumps, and main propellant valves. While some traditional rocket engine components could take [15 months](https://www.popsci.com/how-us-3d-printing-rocket-engines#page‑2) to build, an entire Rutherford engine can be 3D printed in less than 24 hours. Rocket Labs’ vertically integrated manufacturing line means they can “roll an Electron vehicle off the production line [every week](https://www.rocketlabusa.com/news/updates/rocket-lab-to-launch-first-commercial-mission-this-month/)”.

This decreased manufacturing time – and the proprietary software to manage it – is key to reaching Rocket Lab’s launch frequency goals. The company is licensed to launch rockets every 72 hours. They chose their private launch site, located on a remote peninsula in New Zealand, for high frequency launches as well. “There’s no shipping, there’s no air traffic, there’s nothing except a [great big piece](https://www.spaceflightinsider.com/missions/commercial/rocket-lab-electron-rutherford-peter-beck-started-first-place/) of blue Pacific Ocean,” says Beck. Without air interference, Rocket Lab can launch as frequently as they please. The company is also licensed to launch out of Wallops Island, where they are building a second launch site with the active encouragement and cooperation of the US Government, as well as Cape Canaveral and the Pacific Spaceport Complex. Collectively, Rocket Lab will be able to reach any orbit of commercial or government interest applicable to its launch vehicles.

High Launch Cadence – but with Care and Competence for the Long-term Win

Rocket Lab is rushing to launch hundreds of smallsats in the coming years, but they aren’t rushing blindly. The company approaches satellite launches with their long-term impact in mind. Space junk — debris from rockets and satellites left orbiting the earth — is a growing concern in the aerospace community. Thousands of large objects (and [hundreds of millions](https://www.esa.int/Safety_Security/Clean_Space/How_many_space_debris_objects_are_currently_in_orbit) of small ones) are currently circling the earth, endangering the satellites whose paths they might cross. Even tiny objects are dangerous at 17,500 miles per hour.

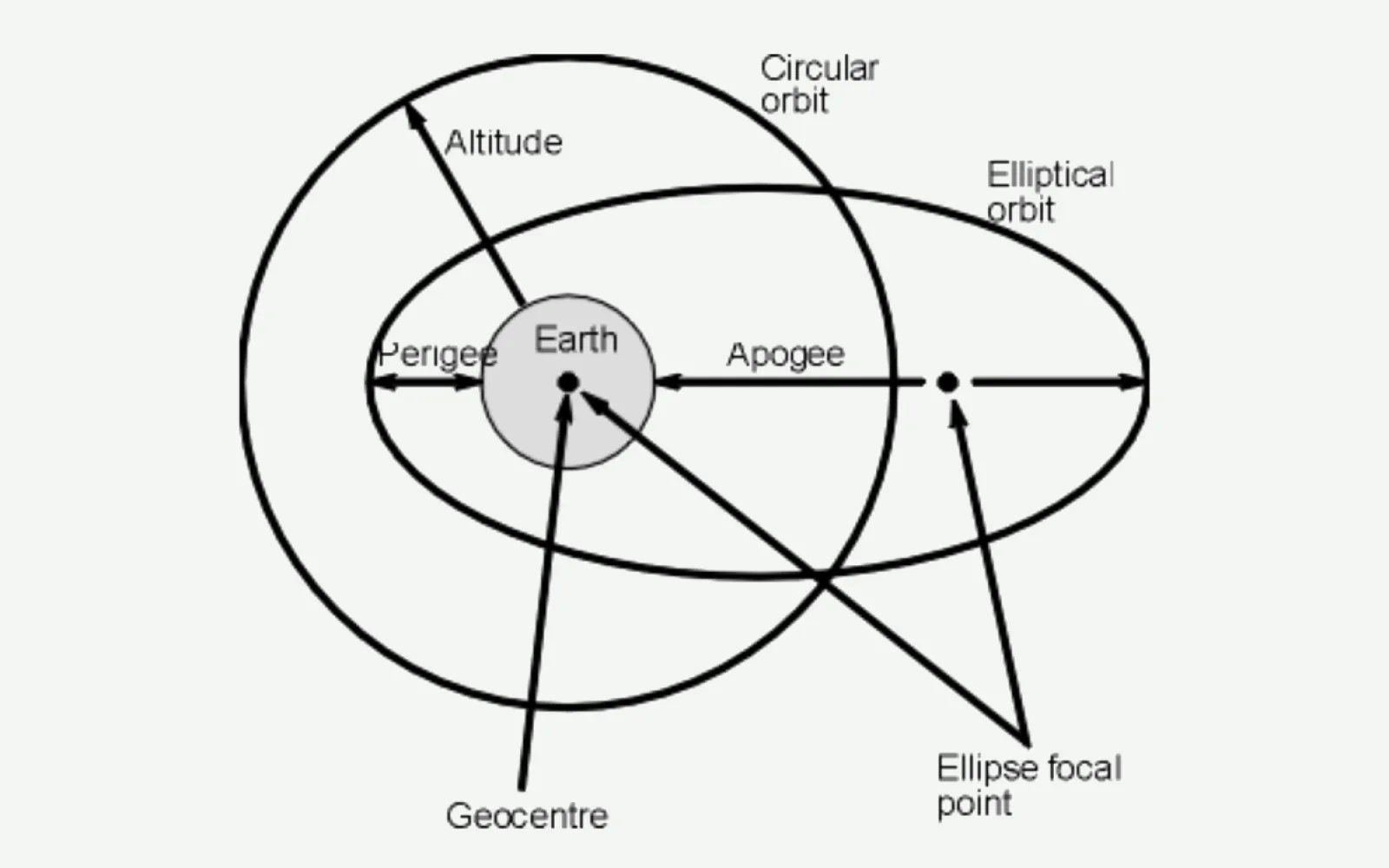

Rocket Lab has designed the Electron rocket to [deorbit](https://www.space.com/41794-rocket-lab-peter-beck-interview.html) after delivering satellites so it doesn’t add to the space junk problem. After launching the rocket with its first stage, most vehicles use their second stage to guide the rocket into the circular orbit its satellites need to be in. The second stage remains in that same orbit. Rocket Lab instead launches their second stage into a highly elliptical orbit, which quickly brings the rocket back to Earth. They instead separate a small stage called the [kick stage](https://spacenews.com/rocket-lab-launch-also-tested-new-kick-stage/) to circularize the smallsats’ orbits. The kick stage then flips around and deorbits itself. Beck [notes](https://www.space.com/41794-rocket-lab-peter-beck-interview.html) that “we really leave only the spacecraft in orbit and not much else”. Soon, not even smallsats will stay in orbit longer than they should — one of the last-minute payloads for Rocket Lab’s November launch is the NABEO drag sail, which brings smallsats back to Earth once they reached the end of their lifespan.

While the company experienced a delay with one summertime launch after a problem with their motor controller, Rocket Lab is all about sustained mission success, not cadence at the cost of explosions and loss to customers (as has sometimes been the choice of certain launch vendors.) CEO [Peter Beck](https://www.space.com/41794-rocket-lab-peter-beck-interview.html) is focused on reliability and long-term high cadence success: “We could have put a vehicle on the pad straight away — we could roll a vehicle out to the pad literally now — but when you roll something out with a known issue, it carries risk … We’re well-backed, so for us it’s really about making sure we don’t take unnecessary risk and [about] bringing a vehicle to market that’s ready to have this high cadence.”

This discipline and care enabled Rocket Lab to complete back-to-back launches for late November 2018 and December 2018, weeks apart, for 20 satellites, including for customers like NASA.

In Summary

DCVC is proud to back Rocket Lab as they make “space open for business.” Rocket Lab’s Electron will carry the wave of smallsats which infrequent and expensive launches provided by other vendors have held back for years. Their manifest is already booked through 2020. Rocket Lab is a critical enabling technology that will foster growth and innovation in the aerospace industry, powered by unique and proprietary software – the best of both worlds from a DCVC perspective. And here’s to out-of-this-world success for Rocket Lab!