Kanvas Biosciences

Mapping the microbiome to improve human health

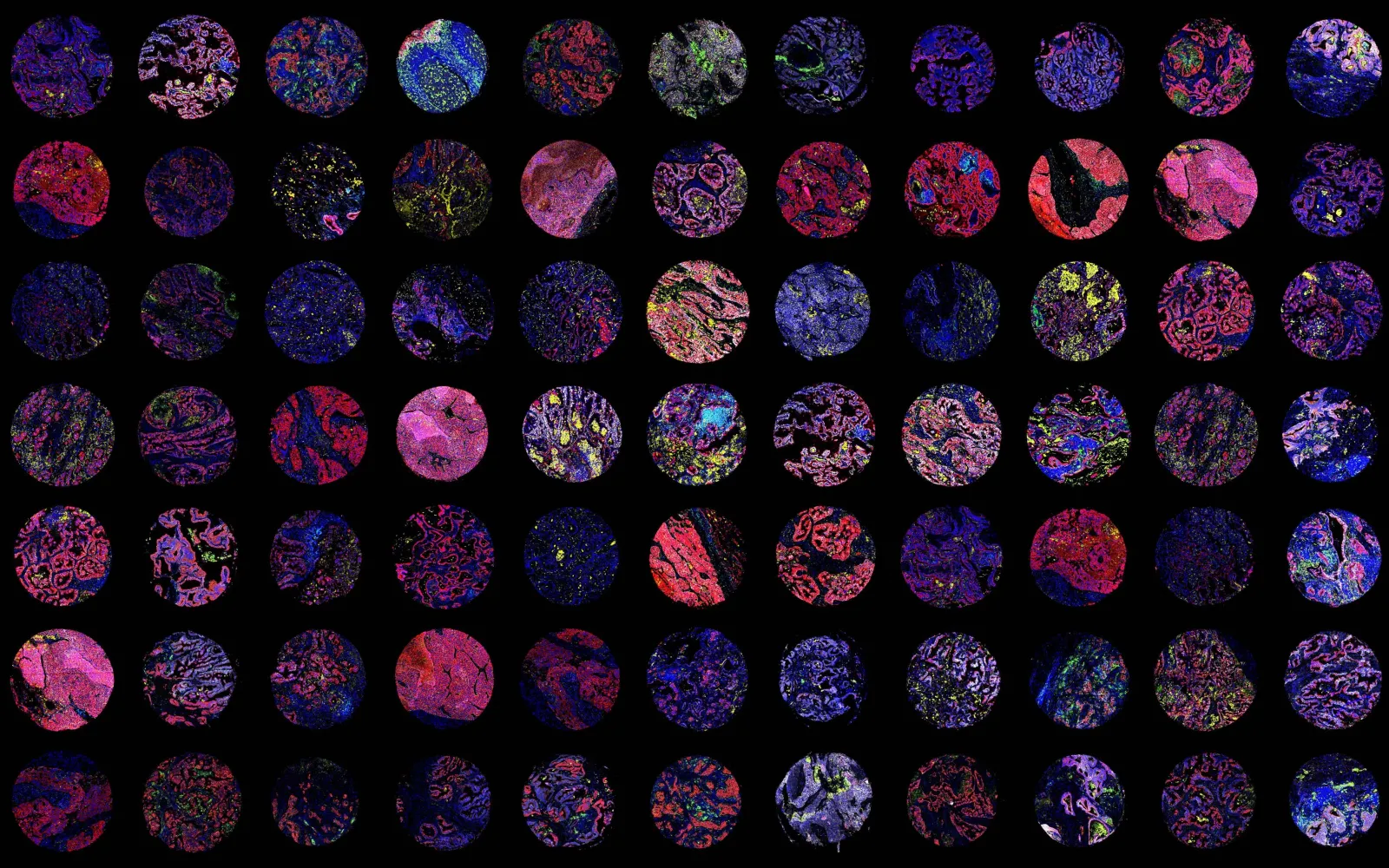

We’ve talked a lot here about Kanvas Biosciences, whose unique computational spatial biology platform is rapidly advancing new drugs into the clinic in an area of therapeutics that has historically disappointed other companies. We’ve highlighted Kanvas’s advanced spectral lightsheet microscopy technology and its work on microbiome products that can boost the action of immune checkpoint inhibitor drugs against cancer. But an untold part of Kanvas’s story is their prowess at in-house manufacturing of precision microbiome therapeutics, or PMTs.

The company decided early on to produce these complex cocktails of live microorganisms at its South San Francisco manufacturing site, which is now the most advanced anaerobic biofermentation facility in the world, rather than farm out the process, as most drug development companies would. That has unlocked a level of product consistency and quality that would be unachievable through outsourcing — while ensuring that the cycle of doing and learning, so invaluable in deep tech, happens onshore in America.

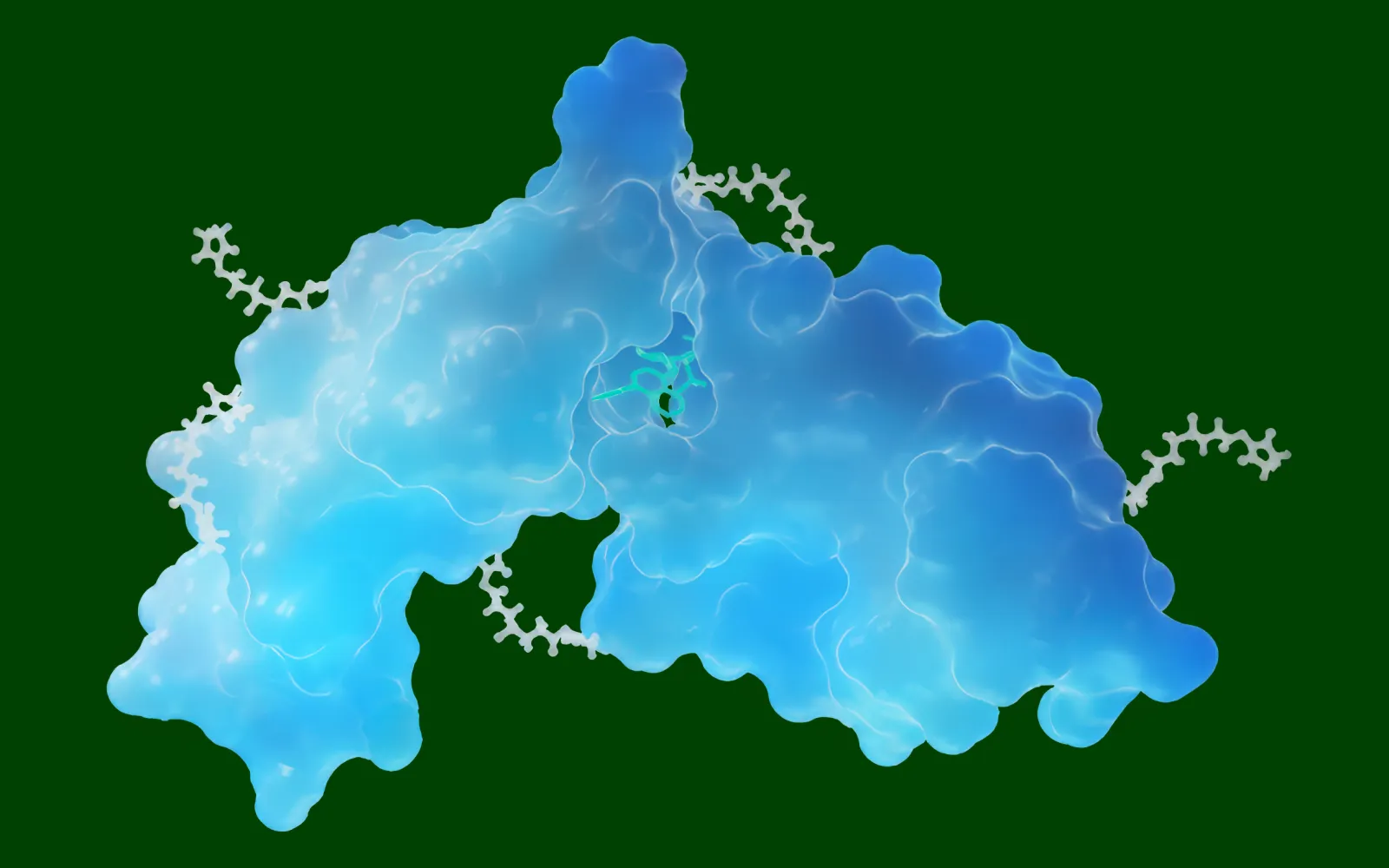

The challenge for Kanvas is that its PMT products, such as its cancer drug candidate KAN-001 (which will enter clinical trials next year), contain dozens of proprietary bacterial strains carefully chosen using the company’s computational and imaging technologies for their ability to modify the microbiome so that common cancer drugs are more effective for many more patients.

Manufacturing these PMTs at scale means fermenting the bacteria in large bioreactors. But only a few of the contract development and manufacturing organizations (CDMOs) that typically take over at this stage can even ferment complex microbiome products at all, let alone under the anaerobic and highly specific conditions required by many of Kanvas’s strains.

On top of that, Kanvas prepares and distributes its live PMTs in liquid-frozen form to enhance viability, which is a demanding process, and one that’s outside the capabilities of other CDMOs — but it’s worthwhile in a field where so many drugs and companies have failed due to quality issues. (I’ve declined to invest in many promising industrial microbiology ventures because the companies couldn’t show they knew how to manufacture or distribute their products at scale.)

Initial efforts to outsource the production of KAN-001 made clear that CDMOs were not up to the task, so Kanvas decided that the best people to solve the manufacturing challenges were the same people who created the drug itself. The team, led by CEO Matt Cheng, applied its deep expertise in microscopy and computation to develop a unique approach to large-scale precision fermentation of PMTs.

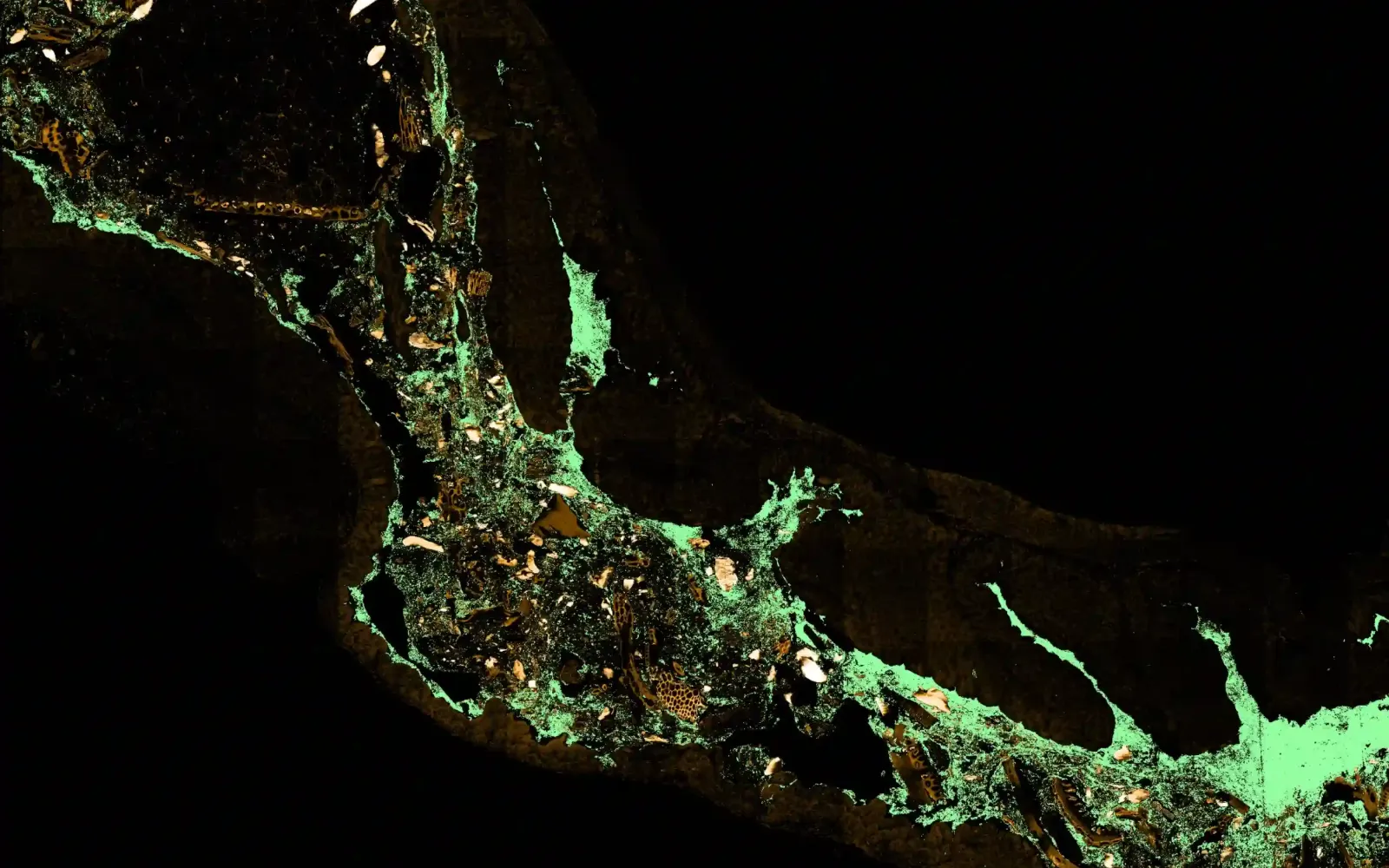

One key ingredient is data from Kanvas’s spatial biology platform, which can show not only how microbial communities are organized in the gut but how they interact with host cells and with one another at the level of gene activity and RNA transcription. These insights help the team identify synergistic strain interactions — for instance, succinate-producing Bacteroides spp. can make food for succinate-consuming Dialister succinatiphilus. That guides the design of discrete co-fermentation groups with stable communities and reduced inter-strain competition.

The company also built proprietary AI models to accelerate its process development. As an example, using the spatial biology data, growth measurements, genome data, and other information as input, the company’s AI can recommend exactly which strains to combine in particular densities to build a drug substance group. Measurements taken at the end of the bioreactor process are fed back into the model, which adjusts its recommendations for the next batch.

Again, the company’s computational and imaging technology is critical here, allowing Kanvas to count individual cells, measure their relative abundance, and make sure each strain is thriving. This AI-driven cycle, with data from bioreactors in the loop, moves Kanvas closer to an optimal final product with each round of fermentation.

Kanvas is already using its process to make KAN-001, and it’s proven to be robust and repeatable, yielding the same mix of microbes every time. In fact, Kanvas is the only company in the world with the capacity to manufacture complex microbiome products completely under anaerobic conditions and deliver a liquid-frozen product. As such, it’s already being asked to handle manufacturing for another microbiome company that’s making products to treat irritable bowel disease in dogs.

The biggest benefit Kanvas gets from owning its own manufacturing process may be the opportunity to learn over time, troubleshoot unexpected issues, and drive down costs with each generation of products. It’s one thing to make 250 milliliters of a drug in the lab; it’s something else to make hundreds of liters in a bioreactor. You can only learn the difference by actually scaling up. Iterative innovation loops — the tight coupling between making and learning happening at companies like Kanvas — are one hallmark of a vibrant industrial innovation ecosystem. America still holds a leading position in the global innovation race, and we applaud what Kanvas and other DCVC portfolio companies are doing to keep it there.