Twelve

A carbon-neutral way to produce green jet fuel and plastic

If plastic hadn’t been invented, the saying goes, the elephant would be extinct. Before plastic, carving ivory was one of the few ways to create small, intricate products like buttons. But plastic and many other modern materials — including paints, soaps, solvents, explosives, and synthetic fibers, as well as the fuels that undergird the economy — are all made by digging up hydrocarbons. Our entire material civilization depends on petrochemistry, but hydrocarbons are devastating the environment.

Imagine instead that we could make all that stuff by pulling the carbon out of industrial waste streams rather than the ground. Then plastics manufacturing, jet travel, and many products would be carbon-neutral or even carbon-negative. That’s the vision at Twelve PBC and the reason why DCVC is excited to lead their Series B financing, raising $130 million along with additional funding. We’ve supported the company from its beginning, having led its Series Seed.

Twelve’s CO2Made® products run the gamut: from a CO2-negative component of Procter & Gamble’s Tide laundry detergent, to the E‑Jet® drop-in replacement for fossil-derived jet fuel for Shopify and the U.S. Airforce, to CO2Made® polycarbonate sunglass lenses for the sustainable streetwear brand Pangaia.

It’s just the start. If all the fuels, materials, and chemicals made from fossil feedstocks were made with captured carbon, the result would be a big reduction in greenhouse gas emissions. Replacing fossil feedstocks with renewable carbon from point source or direct air capture could eliminate nearly 10 percent of global greenhouse gas emissions.

Twelve’s CEO, Nicholas Flanders says he was first drawn to carbon capture and reuse after contributing to a study of carbon capture and storage as part of McKinsey’s cleantech practice. Taking CO2 and putting it underground was the only idea folks had at the time, but policy would be needed to make it happen. It didn’t address the root of the problem, which was the continued extraction of fossil carbon. By adding value to captured carbon, market-driven forces would accelerate the scale-up of capture.

The initial idea of using electricity to break down CO2 to make new products originated in Japan during a period of high oil prices in the 1980s, but research stagnated after the energy crisis passed. In the 2010s, interest in the field revived as the necessity to address climate change became more urgent. Twelve’s technology grows out of fundamental research on CO2 electrocatalysis by co-founders Dr. Kendra Kuhl and Dr. Etosha Cave, who earned their PhDs in the Stanford University lab of chemical engineer Thomas Francisco Jaramillo.

The company is working to scale up a form of electrolysis that converts CO2 and water (H2O) into carbon monoxide (CO) and hydrogen (H2). That combination is known as synthesis gas or syngas, and it can replace the petrochemicals in everything from jet fuel to plastic sunglass lenses.

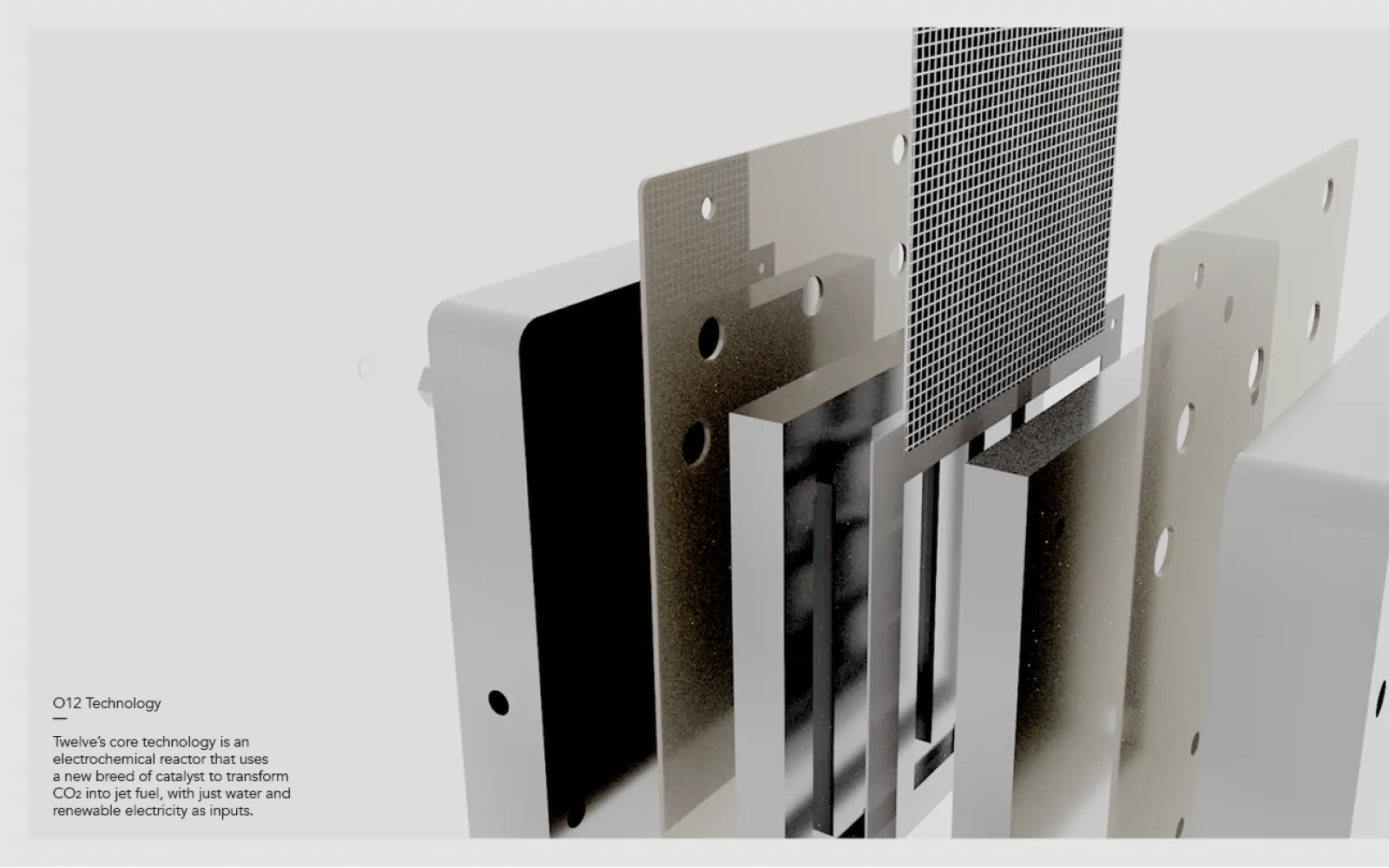

In Twelve’s reactors, voltage is applied to two electrodes on either side of a polymer electrolyte membrane. CO2 is fed to the cathode, where nanoscale catalysts enable the production of syngas, while water is fed to the anode, where catalysts enable the production of oxygen. Twelve developed a unique architecture for the membrane-electrode assembly that allows it to operate at high current density; it can break down gas-phase CO2 captured directly from the air or industrial point sources.

Crucially, the reactor also operates at low temperatures, enabling direct integration with variable sources of electricity like solar and wind. When the electricity for the synthesis comes from renewable sources, the overall process can be carbon-negative — or, at least carbon-neutral — if the resulting carbon compounds are combusted again.

With the Series B funding, Twelve will move beyond lab prototypes and increase the surface area of its CO2 electrolyzer cells to achieve higher throughput. Then it will stack those cells into mass-manufacturable modules, a step that should unlock new economies of scale.

Humanity is on track to achieve a future of carbon-free electricity generation, but we will still need carbon to make essential products, from the cushion in your couch to the insulation in your walls. Twelve is solving the critical engineering challenges so these, and many other products, can be made from captured carbon rather than fossil carbon.

Twelve to Deploy World’s First Industrial-Scale Carbon Transformation Platform — BusinessWire