Unspun

Using 3D weaving to reduce the fashion industry’s climate impact

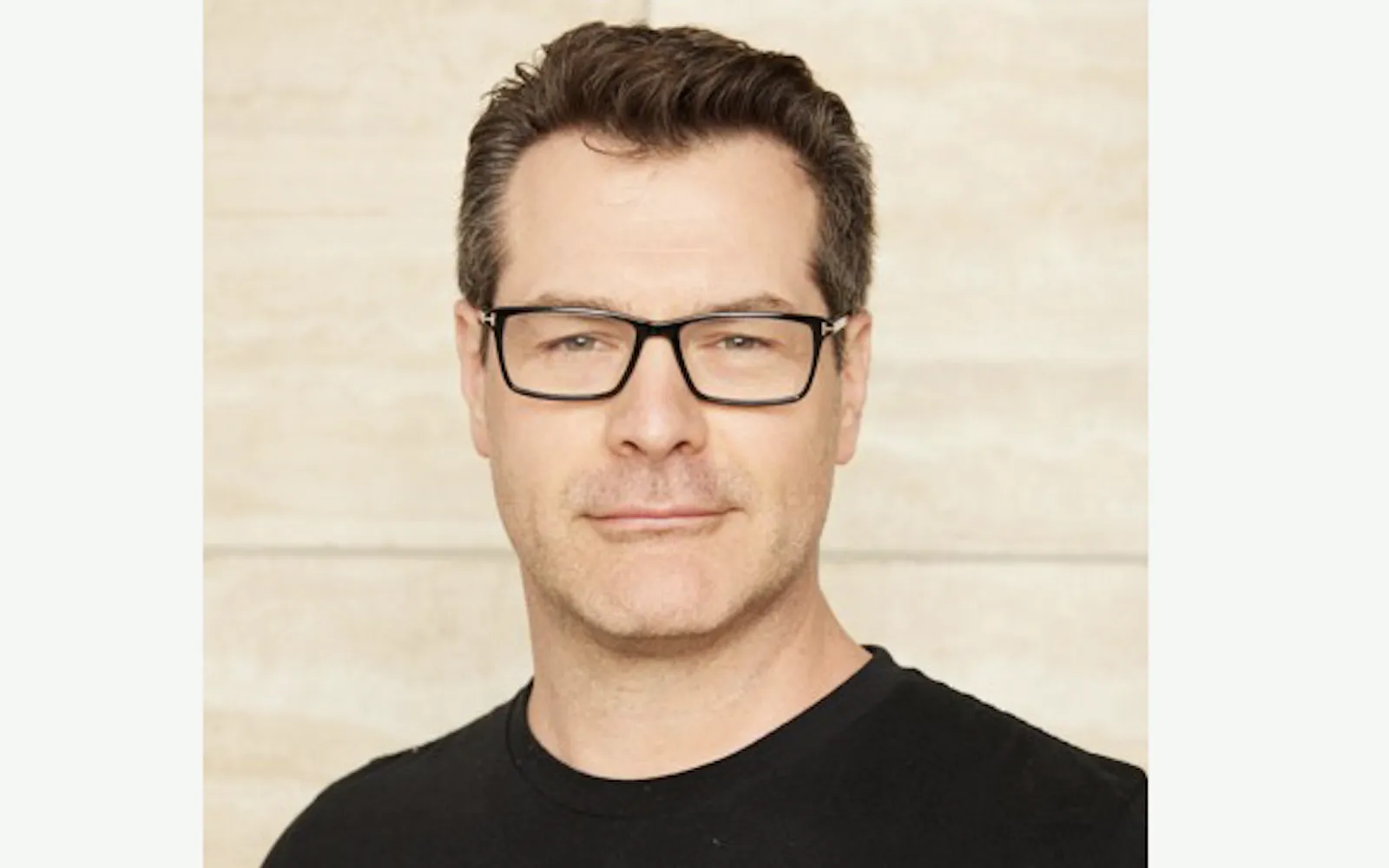

Unspun, the industry leader in 3D weaving technology, announced that it’s welcoming Chris Blakeslee to its board of directors. Having led the company’s oversubscribed $32 million Series B funding round last year, we couldn’t be more pleased. Chris brings 15 years of experience growing some of the world’s leading apparel brands, most recently as president & CEO of Athleta, and before that as president at Alo Yoga and BELLA+CANVAS.

Chris was attracted by the commercial potential of Unspun’s technology, which is designed to enable automated, on-demand apparel production. He explains that while the industry has been able to automate many of its processes, sewing still has to be done in places where there are lots of expert sewers. Unspun’s proprietary Vega 3D weaving technology makes seamless garments a possibility at scale, so instead of products having to travel the world before they hit the market, they can be cut, sewn, and packaged in the place where they’ll be worn. In a notoriously fickle industry where speed to market is critical, the shorter lead times enabled by localized manufacturing are game changing, which is why Unspun already has partnerships with industry heavyweights like Walmart and Decathlon.

Unspun’s technology is one exciting example of a broader reorganization of global supply chains, which are shifting from centralized to decentralized models. We spent the past 40 years moving the production of everything abroad, but the Covid pandemic and other shocks have forced us to come to the realization that we have to build back our industrial muscle at home. But we’re not building it the same way; people are hungry for cutting-edge, modular, fully electrified and automated technologies that are cost-competitive with legacy systems.

I caught up to Chris while he was getting acquainted with the team at Unspun’s Oakland headquarters.

DCVC: What initially drew you to Unspun’s product and mission?

Blakeslee: To this day, with all the progress we’ve made in robotics and automation and AI, sewing garments is one thing that has been virtually unaffected. One way to avoid that is by not having seams at all. I’ve seen tubular garment manufacturing many times over the years, because in the t‑shirt world, there was a time when every t‑shirt was tubular, meaning it had no side seam, so you have a straight tube top to bottom. The problem is that people aren’t shaped like that, so fit is a major issue. When I saw Unspun’s technology, it was the first time that I had seen a machine that was using technology to taper a tube out of fabric and actually be able to make something where you get size variation. For pants in particular, I think it’s incredibly novel, and it solves some really significant issues. While it’s not complete automation, it certainly has the potential to replace the vast majority of sewing functions, and I think that could be revolutionary.

DCVC: How will your prior leadership at Athleta, Alo Yoga, and BELLA+CANVAS inform your work with Unspun?

Blakeslee: BELLA+CANVAS produces about 250 million units of apparel per year in its own vertically integrated supply chain. It takes nearly 35,000 employees in seven countries to do it. The point being, when I was there I spent a significant amount of time deep in supply chain and manufacturing— how it was done, where it was done, what the challenges were — and that’s what’s exciting about what Unspun is doing. You have consumers in lots of places around the world, and you have production in very, very few. This technology holds the promise to bring your production very close to your consumer.

But I always tend to see these things through the brand-related lens of how you speak to the consumer, where the benefit they also get is doing right by the planet, doing right by the environment. In this space, there’s been a conversation about environmentally responsible products for a long time — organic cottons and recycled polyesters and on and on — and consumers have voted with their purchases, so if they can get that at the same price, it’s a great tiebreaker.

I think the merger of these two things is the really interesting piece. This industry needs this very forward thinking, youthful sort of energy and new paradigms, new ways of thinking. But at the same time, that has to intersect with the questions of how you make these things scale.

DCVC: What opportunities do you see for Unspun going forward?

Blakeslee: In today’s creator economy, trends are changing faster than ever before — the things that are popular today are not popular tomorrow — and in that world, having long lead times is really tough. Being able to have this type of equipment all over the world, where you’re able to identify a trend, produce fast and limited runs, test the trend, and then scale production — it’s an incredible consumer value proposition.

This technology holds the promise to bring your production very close to your consumer. That, I think, is really compelling. Localization means faster speed to market, greater potential for personalization, and obviously, better economics all around. That’s where the power is, in my opinion, and I think we’re going to weave more of that, no pun intended, into our narrative.